Infrastructure

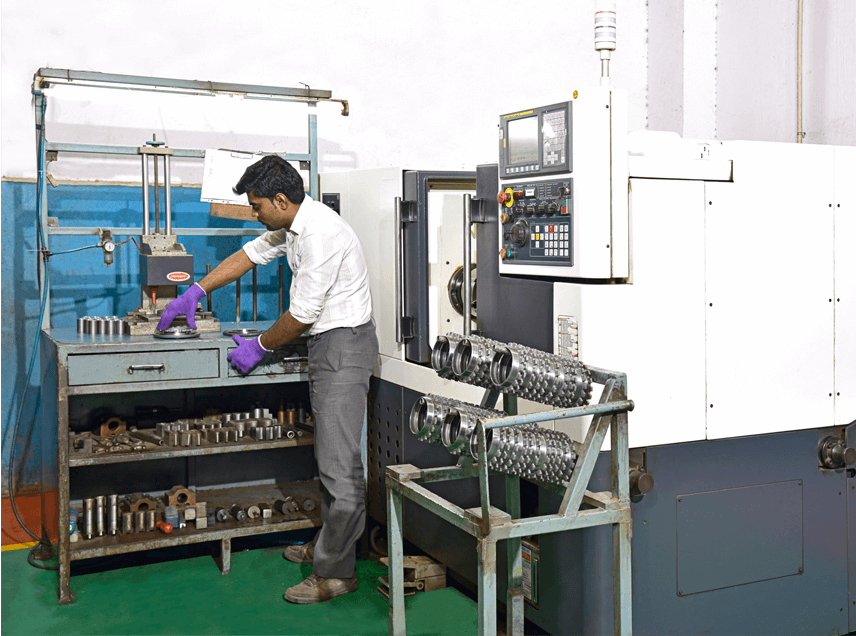

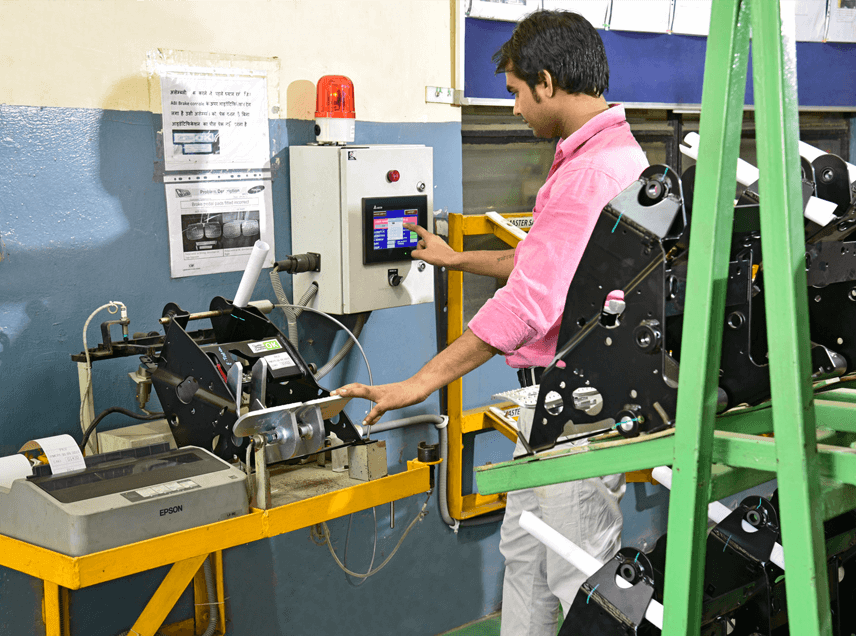

The infrastructure boasts of an unmatched array of technology. Setup comprising cutting edge facilities for Stamping, Forming, NC Tube Bending, CNC Machining, Thread Rolling, Welding, Light Fabrication, Liquid Painting, Powder Coating and General Assembly.

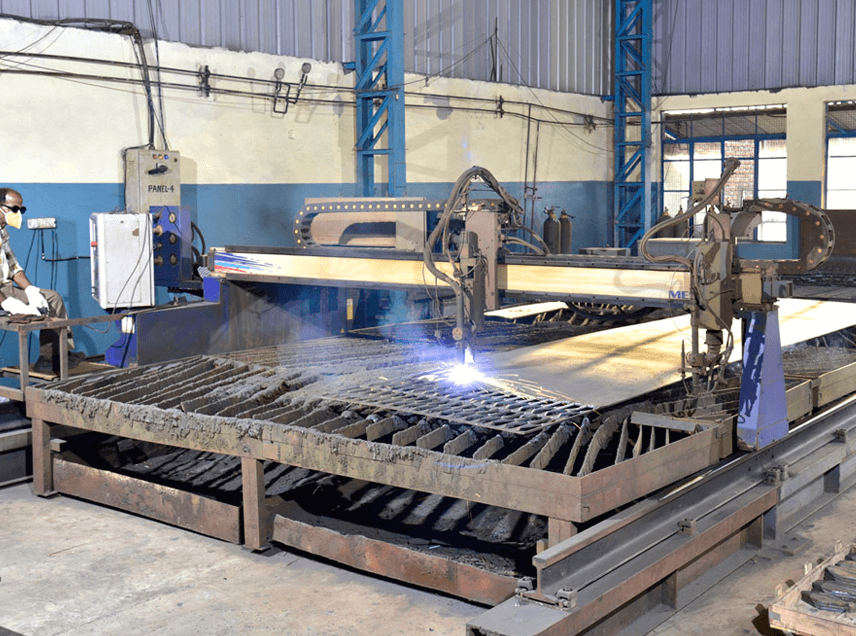

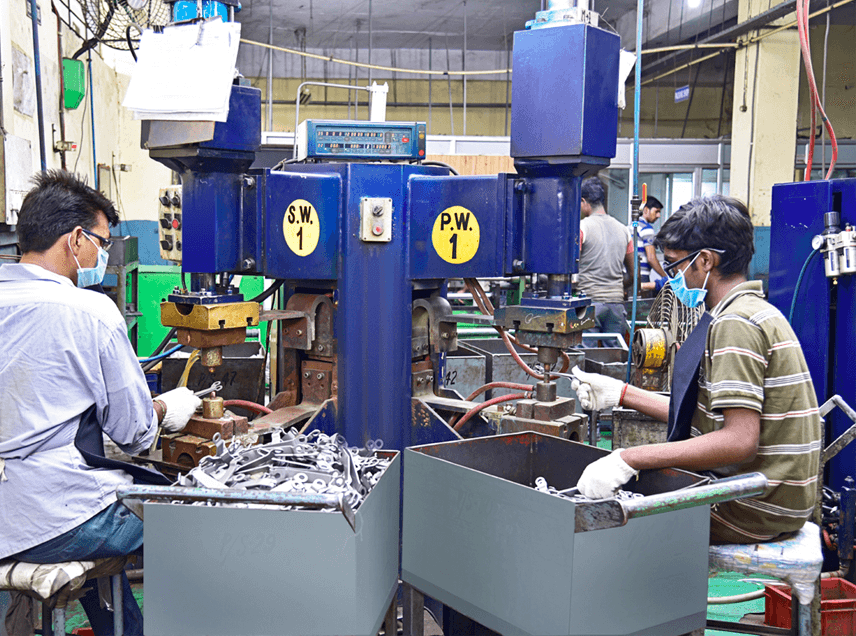

The setup houses latest Plasma Cutting machine ensuring accurate and optimal blanking. For stamping and metal forming operations, the company has installed battery of pneumatic and mechanical power presses with capacities ranging from 10 tons – 250 tons.

Manufacturing of welded components is enabled by a series of Spot welding and Projection welding machines with capacity ranging from 50-100 Kva.

To support fabrication, robotic welding, low cost semi-automated welding SPMs and series of MIG welding stations are available.

To deliver consistent quality tubular components, company has installed two NC Pipe Bending Machines.

Horizontal Broaching Machines are available to fulfill needs of serration for sheet metal components.

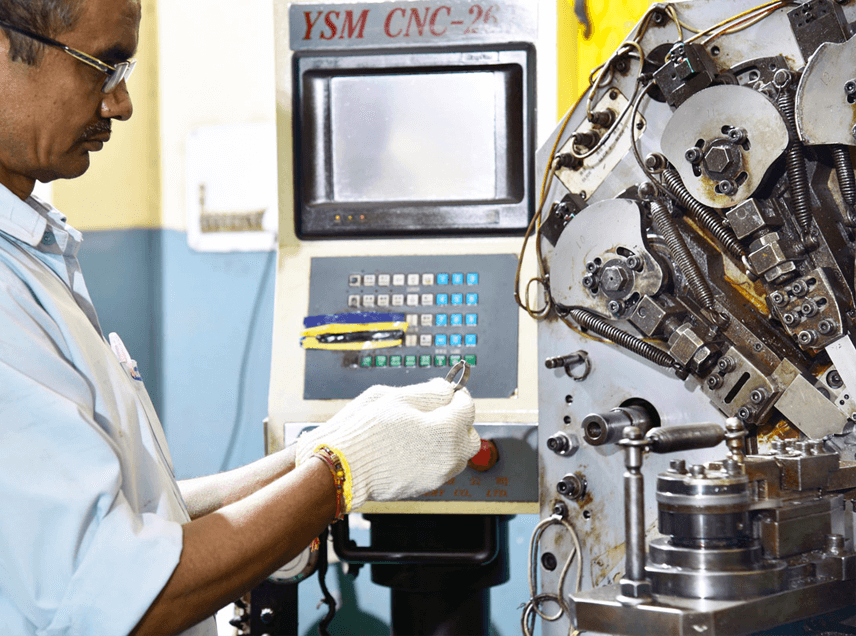

A specialist in manufacturing of Stainless Steel Clamps, Panchal’s production facilities are equipped with two Multi Side CNC Clamp Manufacturing Machines for high volume requirements and, for low volume requirements, separate production lines are available.

Painting Infrastructure

The painting facility is laid with state of art, conveyorized powder coating line and liquid painting line with integrated surface preparation, drying and baking facilities. Baking facility has a provision of recording travelling temperature also for greater process control. The whole setup ensures that the finished products conform to global standards.

The company has in-house paint testing lab with all facilities to ensure coating quality where various tests including salt spray testing, tape testing, impact testing, DFT are conducted.

Tool Room

The company’s tool room is adequately equipped with all necessary equipments to cater the in-house as well as customers’ tooling needs.

Panchal Mfg is known as an innovative indigenous technology developer. To further accelerate production and improve repeatability, the company is developing low cost automations from its tool room along with all production tooling requirements. This enables to increase production efficiency and achieve new breakthroughs in manufacturing.